Optimize systems with professional mechanical system optimisation support.

Optimize systems with professional mechanical system optimisation support.

Blog Article

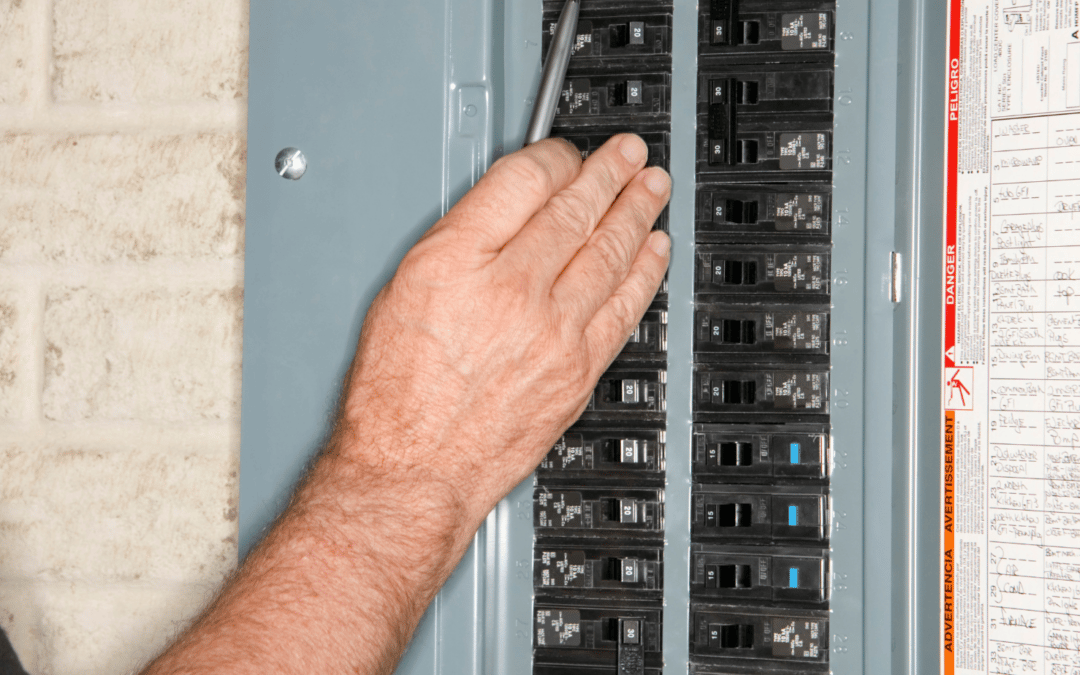

Top Tips for Effective Electric System Troubleshooting

Repairing electric systems calls for a systematic method, based in a detailed understanding of electrical concepts and safety methods. By familiarizing oneself with circuit parts, using essential devices, and adhering to an organized evaluation technique, professionals can properly identify and settle issues. Nonetheless, the nuances of efficient troubleshooting prolong past mere technological knowledge; comprehending just how to document findings and focus on safety can significantly influence results. As we check out these critical elements additionally, it comes to be clear that understanding this process is not just helpful yet essential for success in the field.

Understand the Fundamentals

Comprehending the fundamentals of electrical systems is vital for efficient troubleshooting, as a solid foundation allows specialists to identify and fix problems a lot more effectively. An extensive grasp of electrical principles, such as voltage, existing, resistance, and power, is essential in recognizing the origin of issues. Voltage is the electrical potential distinction that drives existing with a circuit, while resistance opposes the flow of existing, affecting the overall capability of the system.

Experience with circuit parts, including resistors, capacitors, diodes, and switches over, is likewise paramount. Each element plays a distinct function in circuit behavior and can impact efficiency when malfunctioning. Furthermore, recognizing series and identical circuit configurations is crucial, as these arrangements influence the circulation of voltage and current within the system.

Service technicians have to be aware of potential risks, such as shock and short circuits, to apply safe troubleshooting techniques. By grasping these foundational ideas, professionals boost their ability to conduct reliable diagnostics and repair services, inevitably leading to boosted performance and reliability of electric systems (electrical system troubleshooting).

Gather Necessary Equipment

Effective troubleshooting of electrical systems needs the ideal collection of tools to identify and fix problems precisely. A well-appointed professional can significantly enhance efficiency and effectiveness in identifying troubles. Important tools include a multimeter, which measures voltage, current, and resistance, permitting specific analyses of electric elements. Clamp meters are likewise beneficial for determining present without disconnecting the circuit, ensuring safety and convenience.

Additionally, shielded hand tools such as screwdrivers, pliers, and cord strippers are essential for securely controling electrical links. It is likewise suggested to have a circuit tester handy to confirm the presence of voltage in electrical outlets and wires. For more facility systems, a thermal imaging video camera can aid identify overheating elements, indicating possible failings.

Adhere To an Organized Approach

Having collected the ideal devices, the following action in troubleshooting electric systems is to follow an organized method. A methodical method guarantees that technicians can identify mistakes efficiently and precisely, minimizing downtime and preventing unneeded repairs.

Begin by reviewing the system's schematic layouts and specs. Understanding the layout and operational criteria will supply context for detecting issues. Next, isolate the problem location by utilizing a process of elimination. This entails monitoring each element systematically, beginning with the power resource and working towards the lots.

Utilize screening devices, such as multimeters and oscilloscopes, to gather unbiased data about voltage, present, and resistance at various factors within the system. This empirical evidence will certainly direct your troubleshooting efforts and assist to confirm or remove prospective sources of failing.

Furthermore, think about environmental aspects that may affect the system's performance, such as temperature level changes or moisture ingress. A comprehensive inspection of electrical wiring, connections, and elements will certainly make sure that all opportunities are represented.

Document Your Searchings For

Comprehensive paperwork is essential in the troubleshooting process of electric systems. This method not just help in recognizing the root cause of the problem yet also serves as a reference for future fixing efforts.

In addition, keeping a log of components replaced or repairs performed is invaluable. This details sustains stock management and can aid analyze the durability and dependability of particular components.

Inevitably, the paperwork process need to be complete yet concise, enabling very easy retrieval and review - electrical system troubleshooting. By focusing on comprehensive documentation, technicians can develop an important data base that not just aids in current troubleshooting but additionally encourages future upkeep efforts, thereby boosting general system reliability

Prioritize Safety And Security Procedures

Recognizing the intrinsic threats connected with electric systems is important for ensuring safety and security during troubleshooting. Electric shock, burns, and tools damage are just a few of the possible risks that service technicians face. Prioritizing precaution is not just a lawful responsibility but also an ethical imperative that safeguards both the specialist and the surrounding environment.

Before beginning any kind of troubleshooting job, specialists must wear appropriate personal protective devices (PPE), including protected handwear covers, safety and security glasses, and flame-resistant clothing. Making sure that the workspace is completely dry and devoid of clutter can considerably minimize the danger of mishaps. It is vital to de-energize circuits before beginning any work, verifying that they are not find out this here live through the usage of a multimeter or voltage tester.

Developing clear interaction methods with group participants is likewise crucial; this makes sure that everybody understands potential hazards and the status of the electrical system being worked with. Last but not least, having an emergency situation action strategy in location can show indispensable in the event of an event. By focusing on precaution, specialists can efficiently mitigate threats and promote a safer workplace.

Verdict

Efficient electrical system repairing relies upon an extensive my company understanding of fundamental concepts and a methodical approach. By collecting necessary tools, adhering to organized assessment techniques, and thoroughly recording findings, the fixing process becomes a lot more efficient and trusted. Prioritizing safety procedures guarantees the well-being of people included and the integrity of the electrical system. Applying these techniques will certainly improve the troubleshooting experience, causing quicker resolutions and improved operational performance in electrical systems.

Report this page